Here, we are going to discuss the blade in Talc Raymond mill.

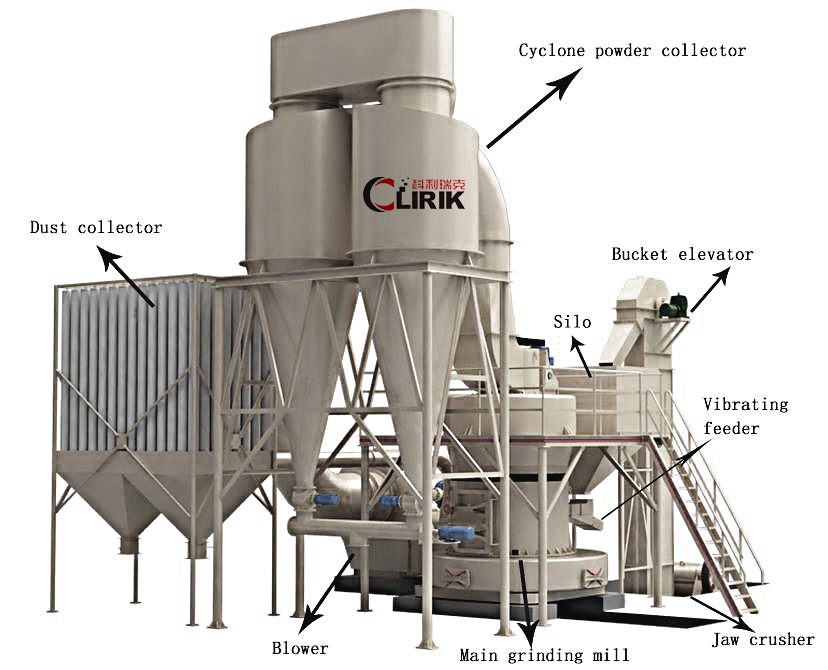

Inside the YGM series high pressure pulverizer, a high pressure spring with more than 1000 kg pressure is fastened on the roller hanger. After starting work, the grinding roll revolves around the spindle and rolls are close to the grinding ring under the action of high-pressure spring and centrifugal force. The rolling pressure is 20% higher than that of other Raymond mill under the same power condition, so the output is greatly increased. When the grinded material enters the grinding chamber, it is rolled between the grinding roll and the grinding ring by the spade. The powder after the grinding is brought into the analyzer with the circulating air of the blower. The qualified fine powder enters into the cyclone collector with the air flow, which is the finished product. The large particles lag behind and are to be re-grinded. The recirculating air returns to the blower to repeat the above process and the remaining wind enters the bag filter to purify. When the grinding roll and ring wear and tear to a certain extent, adjusting the length of high-pressure spring, keeping the constant rolling pressure between the roller and the ring, so as to ensure stable output and fineness.

The mill adopts a convenient and fast impeller adjusting device, so that the clearance between the blade end and the shell of the separator can be adjusted conveniently and quickly. When the speed is constant, increasing the density of the blade can improve the fineness of the finished product. In other words, the rotational speed of high density impeller is lower than that of low density impeller when the fineness of finished product does not need to be changed. By reducing airflow resistance, the output of finished products can be increased by more than 50% under the same power.

We also have talc ultra fine mill, vertical roller mill, ball mill and other mills. Talcum powder coating and packaging machine are also available. Welcome to contact us for any needs. You can chat with us online, leave messages on our website or call us directly.

HOT PRODUCTS

Talc Raymond Mill

Capacity: 1-25 t/h

Max feeding size: 40 mm

Discharge fineness: 50-325 mesh

Range of application: Barite, calcite, potassium feldspar, talc…… [Read More…]

Micro Powder Grinding Mill

Capacity: 0.2-45 t/h

Max feeding size: 20 mm

Discharge fineness: 150-3000 mesh

Range of application: calcium carbonate, kaolin, carbon black, dolomite…… [Read More…]

Talc Ultrafine Grinding Mill

Capacity: 0.2-45 t/h

Max feeding size: 20 mm

Discharge fineness: 150-3000 mesh

Processing materials: non-flammable and explosive non-metallic ores with Mohs hardness less than 7…… [Read More…]

Talc Jaw Crusher

Output Size: 65-160mm

Feed size: 480mm

Capacity: 1-140t/h

Processing materials: Granite, quartz stone, river pebble, calcite, concrete, dolomite…… [Read More…]

Talc Hammer Mill

Output Size: 5-20 mm

Feed size: <350 mm

Capacity: 5-30 t/h

Application: It is widely used for medium and fine crushing of brittle, medium hardness and soft materials... [Read More…]

Talc Vertical Mill

Discharge fineness: 150-3000 mesh

Feed size: <15 mm

Output: 1-20 T/H

Product features: It has high grinding efficiency, low energy consumption, uniform particle shape... [Read More…]