How should talc powder processing enterprises take good measures against dust?

1. Dustproof measures for crushing and crushing processes

All equipment used for crushing, grinding, wheel crushing and other operations should be provided with closed or semi-closed hoods according to the feeding and discharging methods; according to the dust generation point, local closed hoods, overall closed hoods or closed rooms shall be adopted such as different closed methods, open production is not allowed. At the same time, a reasonable exhaust air volume is designed to ensure that a negative pressure is formed in the closed hood, and it should be purified by bag dust removal equipment.

The sealed device should conform to the principles of easy operation, disassembly and maintenance, firm structure, lightness, tight combination and safety, etc. It should not lose its tightness due to vibration or impact of material block and equipment maintenance.

The connection between the equipment and the pipeline, and between the pipeline and the pipeline should be sealed. For dynamic connection, a flexible sealed connection should be used.

Wet crushing equipment shall be used. A continuous water spray device shall be installed above the feed inlet. The lower part of the discharge outlet shall be suitable for sealing and should be airtight and exhausted.

Under the conditions allowed by the process, the ground spraying measures should be adopted in the dust-generating work area. Spraying dust should be used in the process of loading, unloading, transferring, crushing and screening.

2. Dustproof measures in the drying process

For drying equipment, ventilation and dust removal measures should be taken. The dusty gas discharged from the drying equipment has a high temperature and a high humidity, and it should be purified by a wet dust collector. If a dry dust collector is selected, measures to prevent condensation and blockage should be taken.

The discharge port of the drying equipment should be equipped with a closed cover and exhausted.

3. Dustproof measures for grinding equipment

The Talc Raymond Mill wind power system should be operated with positive pressure, and the entire system must be tightly closed.

Generally, an independent dust removal system should be installed for the dust removal of the talc Raymond mill after-wind, and the purification equipment should use a high-efficiency dust collector. Effective measures should be taken to prevent dew condensation and blockage on the dust duct and dry dust collector.

For the large cyclone tube and the existing small cyclone tube used as residual air dust removal, the lower part of the cyclone tube must be installed with a closed discharger or connected to a closed silo.

The powder conveying system of ultrafine grinding must have a good seal. Bag dust collector should be used for powder collection and tail gas purification.

HOT PRODUCTS

Talc Raymond Mill

Capacity: 1-25 t/h

Max feeding size: 40 mm

Discharge fineness: 50-325 mesh

Range of application: Barite, calcite, potassium feldspar, talc…… [Read More…]

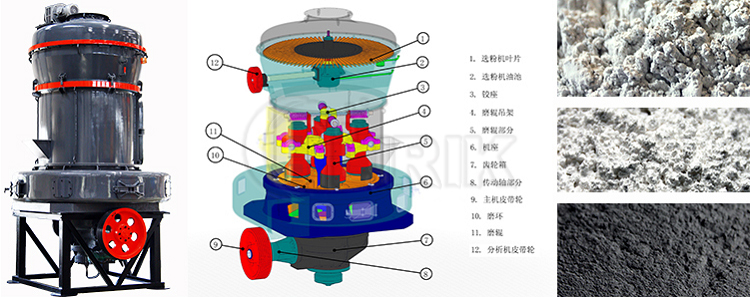

Micro Powder Grinding Mill

Capacity: 0.2-45 t/h

Max feeding size: 20 mm

Discharge fineness: 150-3000 mesh

Range of application: calcium carbonate, kaolin, carbon black, dolomite…… [Read More…]

Talc Ultrafine Grinding Mill

Capacity: 0.2-45 t/h

Max feeding size: 20 mm

Discharge fineness: 150-3000 mesh

Processing materials: non-flammable and explosive non-metallic ores with Mohs hardness less than 7…… [Read More…]

Talc Jaw Crusher

Output Size: 65-160mm

Feed size: 480mm

Capacity: 1-140t/h

Processing materials: Granite, quartz stone, river pebble, calcite, concrete, dolomite…… [Read More…]

Talc Hammer Mill

Output Size: 5-20 mm

Feed size: <350 mm

Capacity: 5-30 t/h

Application: It is widely used for medium and fine crushing of brittle, medium hardness and soft materials... [Read More…]

Talc Vertical Mill

Discharge fineness: 150-3000 mesh

Feed size: <15 mm

Output: 1-20 T/H

Product features: It has high grinding efficiency, low energy consumption, uniform particle shape... [Read More…]