Speaking of Raymond mill characteristics, I believe that many people will not feel strange. As a kind of Raymond mill equipment specially developed for the treatment of talc. What are the differences between talc Raymond mill and common Raymond mill?

The set structure of talc Raymond mill is composed of a host machine, analysis, plumbing, air blower, finished a cyclone separator, jaw crusher, bucket elevator, an electromagnetic vibration feeder, electric motor etc.. The host is composed of a machine frame, Raymond mill inlet volute, blade and grinding roller and grinding ring, shell and motor. The whole working process of talc Raymond mill, the bulk materials by jaw crusher to the desired size, by the elevator will be sent to the material storage hopper, then through the vibration feeder evenly and quantitatively and continuously into the indoor host grinding grinding, grinding the powder by the fan airflow away. Through the analysis of the classification machine, the fineness of the powder with the gas flow through the pipeline into the large cyclone collector, separation and collection, and then discharged through the powder tube is finished powder. The air intake pipe is sucked by the air return pipe at the upper end of the large cyclone collector.

When talc Raymond mill is working. The whole air flow system of talc Raymond mill is closed circulation, and is circulated in the positive and negative pressure state. In the internal grinding chamber by grinding material has certain water content, the grinding heat generated during grinding in indoor gas evaporation changes the gas flow, and the pipeline connection is not tight so that external gas is inhaled, the circulating air volume increased, as this is by adjusting the fan and the air pipe between the host to achieve flow balance, and small excess gas into the cyclone collector, the fine powder into the residual gas collected, then the cyclone collector upper exhaust pipe into the atmosphere, or into the dust collector in the exhaust gas purification.

HOT PRODUCTS

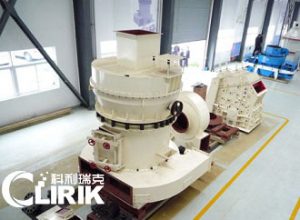

Talc Raymond Mill

Capacity: 1-25 t/h

Max feeding size: 40 mm

Discharge fineness: 50-325 mesh

Range of application: Barite, calcite, potassium feldspar, talc…… [Read More…]

Micro Powder Grinding Mill

Capacity: 0.2-45 t/h

Max feeding size: 20 mm

Discharge fineness: 150-3000 mesh

Range of application: calcium carbonate, kaolin, carbon black, dolomite…… [Read More…]

Talc Ultrafine Grinding Mill

Capacity: 0.2-45 t/h

Max feeding size: 20 mm

Discharge fineness: 150-3000 mesh

Processing materials: non-flammable and explosive non-metallic ores with Mohs hardness less than 7…… [Read More…]

Talc Jaw Crusher

Output Size: 65-160mm

Feed size: 480mm

Capacity: 1-140t/h

Processing materials: Granite, quartz stone, river pebble, calcite, concrete, dolomite…… [Read More…]

Talc Hammer Mill

Output Size: 5-20 mm

Feed size: <350 mm

Capacity: 5-30 t/h

Application: It is widely used for medium and fine crushing of brittle, medium hardness and soft materials... [Read More…]

Talc Vertical Mill

Discharge fineness: 150-3000 mesh

Feed size: <15 mm

Output: 1-20 T/H

Product features: It has high grinding efficiency, low energy consumption, uniform particle shape... [Read More…]