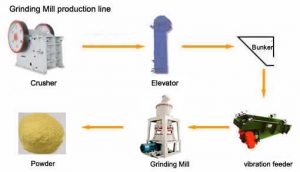

Configuration of talc grinding mill

Talc grinding mill consists of bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone collector, pulse duster system, high pressure positive blower, air compressors and electrical control systems.

Application of talc grinding mill

Talc grinding mill is suitable to grind the material with middle and low hardness such as limestone, dolomite, kaolin, talc, mica, bentonite. It is widely used in the industries like paper, rubber, plastic, packing, cosmetic, chemical products and so on.

Working principle of talc grinding mill

Vibrating feeder evenly send materials into the host and continuously grinding in mill room, after grinding, the powder will flow up by the wind machine, and classified by the classifier, the standard powder will flow through the pipe into the powder collector, the collection is separated by a valve discharge, and this is the final product.

Technical Advantages of talc grinding mill

It can greatly reduced the dust pollution.

High efficiency and low consmption.

High-end material make the machine can work long time.

Evev particle size.

High safety performance and good stability.

More information about our talc grinding mill, welcome to visit our website. Our technical staff would contact you as soon as possible.

HOT PRODUCTS

Talc Raymond Mill

Capacity: 1-25 t/h

Max feeding size: 40 mm

Discharge fineness: 50-325 mesh

Range of application: Barite, calcite, potassium feldspar, talc…… [Read More…]

Micro Powder Grinding Mill

Capacity: 0.2-45 t/h

Max feeding size: 20 mm

Discharge fineness: 150-3000 mesh

Range of application: calcium carbonate, kaolin, carbon black, dolomite…… [Read More…]

Talc Ultrafine Grinding Mill

Capacity: 0.2-45 t/h

Max feeding size: 20 mm

Discharge fineness: 150-3000 mesh

Processing materials: non-flammable and explosive non-metallic ores with Mohs hardness less than 7…… [Read More…]

Talc Jaw Crusher

Output Size: 65-160mm

Feed size: 480mm

Capacity: 1-140t/h

Processing materials: Granite, quartz stone, river pebble, calcite, concrete, dolomite…… [Read More…]

Talc Hammer Mill

Output Size: 5-20 mm

Feed size: <350 mm

Capacity: 5-30 t/h

Application: It is widely used for medium and fine crushing of brittle, medium hardness and soft materials... [Read More…]

Talc Vertical Mill

Discharge fineness: 150-3000 mesh

Feed size: <15 mm

Output: 1-20 T/H

Product features: It has high grinding efficiency, low energy consumption, uniform particle shape... [Read More…]