Putty powder is a kind of building decoration material, and its main component is talcum powder and glue. Putty powder is commonly used for interior and exterior walls. The outer wall putty powder should resist the wind and the sun, so the glue is large, the strength is high, and the environmental protection index is slightly lower. The internal wall putty powder has a good comprehensive index, which is healthy and environmentally friendly. Putty powder is usually gypsum or cement based, so that the surface is rough and makes it easier to bond firmly. However, during the construction, it is necessary to apply a layer of interfacial agent on the base layer to seal the base layer and improve the adhesion of the wall surface, so that the putty powder can be better bonded to the base surface.

It is formulated with a small amount of paint base, a large amount of filler and an appropriate amount of coloring pigment. The pigments used are mainly iron red, carbon black, chrome yellow and the like. The filler is mainly calcium carbonate and talc.

Internal wall water-resistant putty: heavy calcium (or talcum powder) 70% ~ 80%, gray calcium (lime powder) 20% ~ 30%, plus fiber appropriate amount of cellulose.

Exterior wall water-resistant putty: stone powder + gray calcium + cement + cellulose + rubber powder (EVA, PVA).

Our company can offer you with ultra fine talcum powder making machine.

Putty powder superfine mill( Ultra fine talcum powder making machine) product advantage

- It has the advantages of high fineness, high output, low energy consumption and low investment. The crushing capacity of the HCH ultra-fine ring roll mill is more than double that of similar equipment.

- The equipment system can achieve the two processes of ultra-fine pulverization and super-segmentation at the same time.

- The fineness of the finished product is arbitrarily adjusted between 0.04-0.005mm (400-2500 mesh).

- Environmentally friendly production: equipment operation noise is small, dust removal efficiency is high, no dust pollution.

HOT PRODUCTS

Talc Raymond Mill

Capacity: 1-25 t/h

Max feeding size: 40 mm

Discharge fineness: 50-325 mesh

Range of application: Barite, calcite, potassium feldspar, talc…… [Read More…]

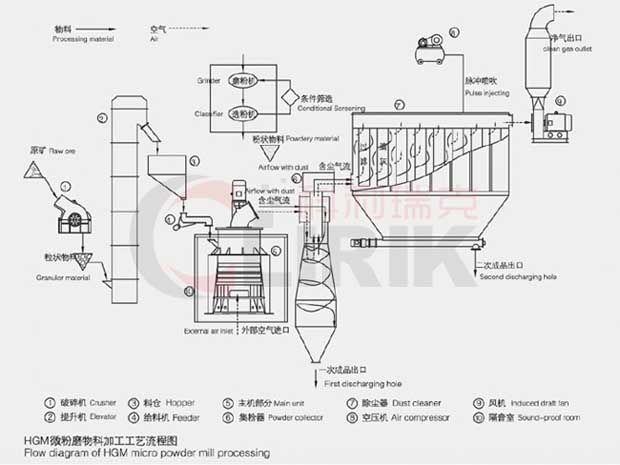

Micro Powder Grinding Mill

Capacity: 0.2-45 t/h

Max feeding size: 20 mm

Discharge fineness: 150-3000 mesh

Range of application: calcium carbonate, kaolin, carbon black, dolomite…… [Read More…]

Talc Ultrafine Grinding Mill

Capacity: 0.2-45 t/h

Max feeding size: 20 mm

Discharge fineness: 150-3000 mesh

Processing materials: non-flammable and explosive non-metallic ores with Mohs hardness less than 7…… [Read More…]

Talc Jaw Crusher

Output Size: 65-160mm

Feed size: 480mm

Capacity: 1-140t/h

Processing materials: Granite, quartz stone, river pebble, calcite, concrete, dolomite…… [Read More…]

Talc Hammer Mill

Output Size: 5-20 mm

Feed size: <350 mm

Capacity: 5-30 t/h

Application: It is widely used for medium and fine crushing of brittle, medium hardness and soft materials... [Read More…]

Talc Vertical Mill

Discharge fineness: 150-3000 mesh

Feed size: <15 mm

Output: 1-20 T/H

Product features: It has high grinding efficiency, low energy consumption, uniform particle shape... [Read More…]