Talc is often used in lotions, beauty powders, and body powders. When talc is used as a skin protection agent, it is often used together with zinc oxide, boric acid, starch, etc. as a withdrawal agent for tweezers or dermatitis. Cosmetic grade talcum powder is often used as a lubricant for powdery cosmetics such as talcum powder. However, since talc is one of minerals, it is buried underground with serpentine containing asbestos, and therefore often contains in natural form. Asbestos ingredients, which are not allowed in the asbestos composition. The true cosmetic grade talcum powder does not corrode the body and smooth bodybuilding, and its performance is stable and does not have a chemical reaction.

As an inorganic filler, talcum can improve the rigidity, strength, hardness and lubricity of the product. With the development and needs of modern industry, the performance improvement of talc is also critical.

Why should talc be surface modified? As with other non-metallic mineral powder materials, the surface organic treatment of talc is necessary. This is because the surface of the talc contains a hydrophilic group and has a high surface energy. In addition, talc powder has great differences in chemical structure and physical form between inorganic fillers and organic polymer molecular materials. It lacks affinity and needs to be surface treated to improve talc powder and polymer. The interfacial bonding force between the two improves the uniform dispersion and compatibility of the talc particles and the polymer. When ultrafine talc is used in coatings, due to its large surface area, it requires a lot of wetting dispersion, which is not easily dispersed and affects the performance of the coating.

The surface coating modification method is to cover the surface of the particles with a surfactant or a coupling agent, and the surfactant or the coupling agent is bonded to the surface of the particles by adsorption or chemical bonding, thereby imparting new properties to the particles.

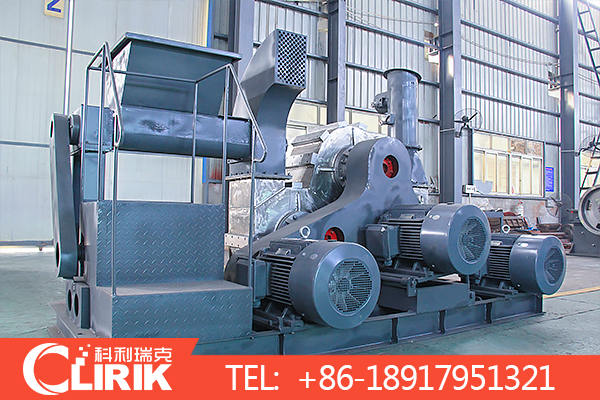

CLG powder surface coating machine is designed to modify the mineral powder like talcum, calcium carbonate, carbon black and etc. This machine, produced by us( Shanghai Clirik Machinery Company), has been exported to several countries.

- This machine can run continuously and has a large processing capacity, which is suitable for industrial production of various scales.

- The use rate of the modified agent is high, the dosage is small, the powder coating rate and the activation index are high, and the energy consumption is low.

- The equipment has both modification and dispersing functions. It is suitable for materials with various fineness. It has unique modification and activation effect on materials with small pseudo-specific gravity and large volume-to-weight ratio such as white carbon black, mica powder and talcum powder.

- The high-speed gas-solid phase vortex mixing operation of powder and medicament has high modification efficiency and basically does not destroy the original grain shape of the powder.

- The hot-cooling machine is completed without the need of a separate heating and cooling system to simplify the operation.

If you have any problem about the CLG talcum powder surface coating machine, you can contact us at any time. You can chat with us online or leaving messages on our website. The feedback will be given within 12 hours.

HOT PRODUCTS

Talc Raymond Mill

Capacity: 1-25 t/h

Max feeding size: 40 mm

Discharge fineness: 50-325 mesh

Range of application: Barite, calcite, potassium feldspar, talc…… [Read More…]

Micro Powder Grinding Mill

Capacity: 0.2-45 t/h

Max feeding size: 20 mm

Discharge fineness: 150-3000 mesh

Range of application: calcium carbonate, kaolin, carbon black, dolomite…… [Read More…]

Talc Ultrafine Grinding Mill

Capacity: 0.2-45 t/h

Max feeding size: 20 mm

Discharge fineness: 150-3000 mesh

Processing materials: non-flammable and explosive non-metallic ores with Mohs hardness less than 7…… [Read More…]

Talc Jaw Crusher

Output Size: 65-160mm

Feed size: 480mm

Capacity: 1-140t/h

Processing materials: Granite, quartz stone, river pebble, calcite, concrete, dolomite…… [Read More…]

Talc Hammer Mill

Output Size: 5-20 mm

Feed size: <350 mm

Capacity: 5-30 t/h

Application: It is widely used for medium and fine crushing of brittle, medium hardness and soft materials... [Read More…]

Talc Vertical Mill

Discharge fineness: 150-3000 mesh

Feed size: <15 mm

Output: 1-20 T/H

Product features: It has high grinding efficiency, low energy consumption, uniform particle shape... [Read More…]